Power Supplies

Control of Heated Moulds

Kontakt

Voltage Supplies for Small and Large Heated Areas

CoTexx® Knitted Heating Fabric has the great advantage that it can be operated with extra low voltage (e.g. <60 V DC voltage without special electric shock protection) as well as low voltage <400 V. With a voltage of >60 V DC or >25 V AC, heating elements and contacts must be protected against accidental contact. In this case, it is advisable to have the heating system checked by an electrician before initial operation.

As with any heating element, the resistance connected to the voltage source must match the voltage. This ensures to reach a heat output as calculated in the design phase.

As a rule of thumb for economical heating of fiber composite components: Small heating area, low voltage – large heating area, high voltage.

The Basic Principle:

Measure and Control Temperature

Regardless of the choice of power supply, the temperature in each heating field must be monitored. For this purpose, a temperature sensor (PT 100, PT1000) or a thermocouple is laminated or glued into the mould or the fiber composite component to be heated. It measures the current temperature of the heating element. With the help of a heating control unit, the setpoint and actual temperature can now be compared and the heating element can be supplied with voltage if required.

In addition, each heating field should have a safety circuit. An additional measuring point monitors the temperature at a meaningful position (ideally at the potentially hottest part of the mold) and gives the signal to switch off the power supply in the event of overtemperature.

Economical and Efficient

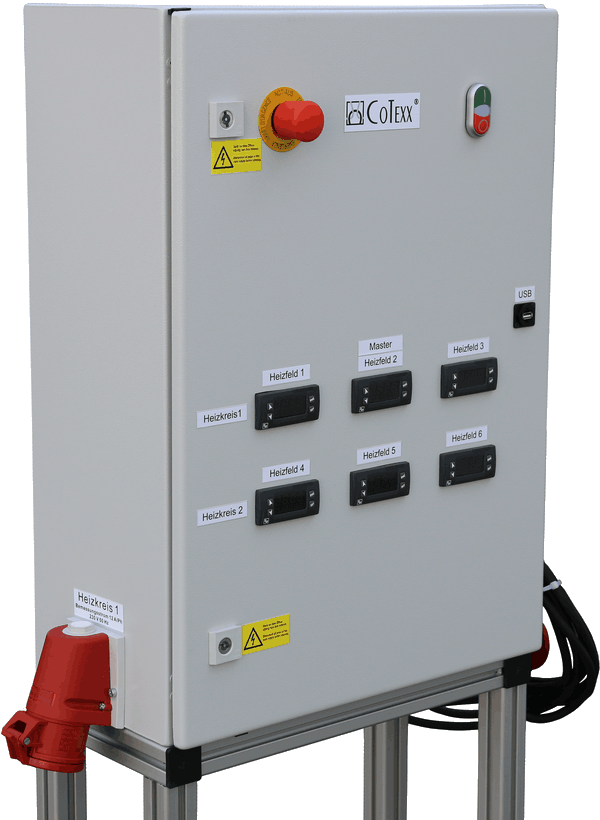

Intelligent Heating Controls from CoTexx

For initial tests with CoTexx® knitted fabrics or a test run of a new heated form, a laboratory power supply is usually sufficient. The voltage can be regulated via a built-in potentiometer to reduce the heating output. The specialist trade offers a large selection of laboratory power supplies with up to 1 kW power and voltages up to 60 V.

In addition, we also offer individual heating controls with and without a voltage source, specially designed for your application.

Controller Box for Laboratory Power Supply

Many laboratory power supplies have a remote control connection. In combination with the CoTexx® control box, the temperature of the heating fields can be controlled automatically.

For this purpose, the cables of the temperature sensor are plugged into the controller box. In the built-in controller, optionally in two-point or PID version, the current temperature is compared with the temperature set in the controller. If necessary, a signal is sent to the laboratory power supply to supply the heating element with voltage. The operating voltage can be adjusted by a potentiometer.

With the controller box shown left, four heating fields or four laboratory power supplies can be controlled. Also available are controllers with programmable temperature profiles.

PID Control with Internal Switching Power Supplies up to 60 V DC

For larger heating projects we offer control cabinets in which switching power supplies with up to 60 VDC are installed. The advantage of this solution is that power supply and control are combined in just one compact device.

We offer a wide variety of designs and output power values. The standard output power can be up to 9 kW, which means that even large areas of 10 m² and more can be supplied with safe extra-low voltage. It is also possible to record the temperature measurements over the heating cycle. The data can be read out via USB and evaluated and documented on the computer.

Of course, you have the choice whether you want to measure temperatures with temperature sensors (PT 100, PT 1000, two-wire, three-wire or four-wire technology) or thermocouples (e.g. type K). We comply with your ideas!

PID Temperature Control for Supplying Heating Elements with 230 V AC

Larger areas can be operated most cost-effective with 230 V or 100 V mains voltage. With the aid of solid state relays, the heating elements are supplied with clocked mains voltage depending on the heat requirement. All relevant settings and measured values are shown on displays, e.g. the current heating power, the energy consumption of a heating cycle or the setpoint and actual temperatures.

All of our control cabinets have extensive safety and shutdown devices to ensure the highest possible level of safety when operating the heated moulds and tools.